- Home

- >

- Products

- >

- Antistatic VCI Film

- >

Product overview:

VCI plastic film is made of polyolefin resin as base material, volatile corrosion inhibitor (VCI) added, and a series of processes. VCI film is mainly presented in the form of bag or sheet in practical application (see product status for details). The packaging protects customers' products and integrates antirust and packaging functions. The thickness, color, size and form of our film are customized and personalized according to the actual needs of customers. The antistatic VCI film has good antistatic property, and its surface resistivity is (108~1012) Ω.

Product model: SF/DF.J-□□

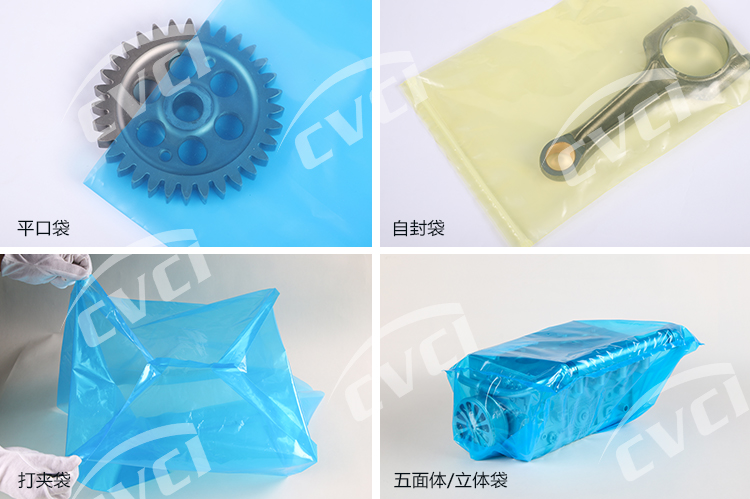

Product form:

Flat bag, three-dimensional bag, clip bag, self-sealing bag, roll material, sheet material.

Performance characteristics:

Antistatic VCI Film is made of VCI master batch and LDPE resin for extrusion and blow molding. Antistatic VCI Film has good antirust function for ferrous metals, copper, aluminum and other metals. The surface resistivity of the product is (108~1012) Ω, with good antistatic performance.

Scope of application:

Antistatic VCI Film is used for rust prevention of metal products such as steel, iron, aluminum, aluminum alloy, copper, silicon steel, phosphating, galvanized plate, tinplate, color coated plate, etc. Antistatic VCI Film has good compatibility with rubber and fiber products, and is suitable for antirust protection of electronic equipment and precision electrical appliances such as integrated circuit boards, printed circuit boards, communication equipment, etc.

Usage method:

Clean and dry the metal equipment, or put it into the VCI plastic film packaging bag after oil treatment and drying, and seal after removing the excess air in the bag. The sealed metal surface shall be free of residual sweat, water film, acid and alkali or other dirt and rust. Unless otherwise stated and verified, VCI materials cannot generally be used in optical devices and products of highly explosive substances and associated propellants.