Product description:

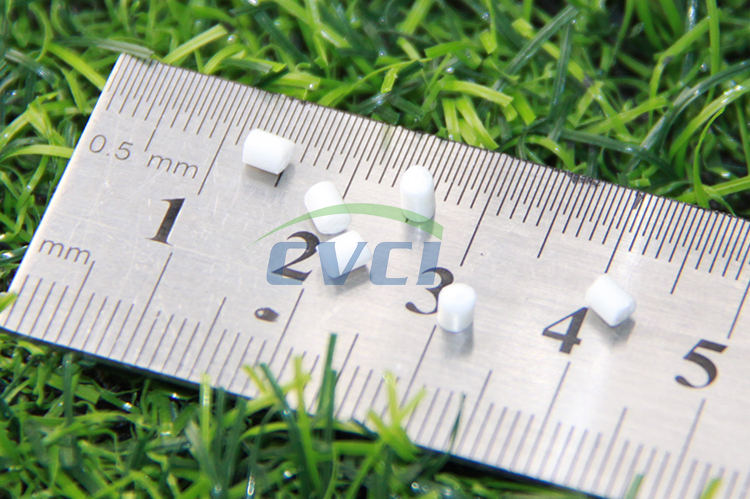

Environment Friendly VCI Masterbatch is a kind of white to milky green VCI antirust masterbatch produced by extrusion from polyolefin resin, VCI and other additives. Environment Friendly VCI Masterbatch is mainly used for antirust protection of ferrous and non-ferrous metals.

Product features:

● No nitrite or secondary amine.;

● Environment Friendly VCI Masterbatch does not contain phosphate, chromium or other heavy metals that may be harmful to human body or environment;

● The VCI component has only a slight and mild smell and no irritation.;

● VCI's antirust protection can penetrate into the inner cavity and deep hole of the workpiece;

● Does not affect any electrical operation or equipment use;

● There is no residue on the surface, and surface treatment is hardly required.

● Save customers indirect costs such as cleaning, corrosion losses and product complaints.

Safety indicator:

Comply with REACH, RoHS and TRGS615 regulations.

Product application:

Environment Friendly VCI Masterbatch is applicable to the VCI film for industrial packaging produced by extrusion blow molding. Applicable metals: steel (carbon steel, stainless steel), iron, cast iron, copper and copper alloy, zinc and zinc alloy, aluminum alloy and other metals.

Matters needing attention:

1. Base material resin: blow film grade polyethylene resin (LDPE/LLDPE/MDPE/HDPE).

2. Addition ratio: single-layer film 80-100 μ m, recommended addition ratio is 2% - 3%.

3. Blow film temperature: extrusion blow molding, processing temperature is lower than 197 ℃.

4. When producing antirust film, the working environment should be kept ventilated and dry.

5. The remaining Environment Friendly VCI Masterbatch after processing shall be re-packed with moisture-proof packaging for use.

Storage:

● Environment Friendly VCI Masterbatch shall be stored in a cool and dry place with the temperature between 18 ℃ and 25 ℃.

● Avoid direct sunlight and contact with fire sources and polluting substances.

● Sealed storage, with a shelf life of 1 year.

Packing method:

Carton barrel, box type, or agreement with customers.