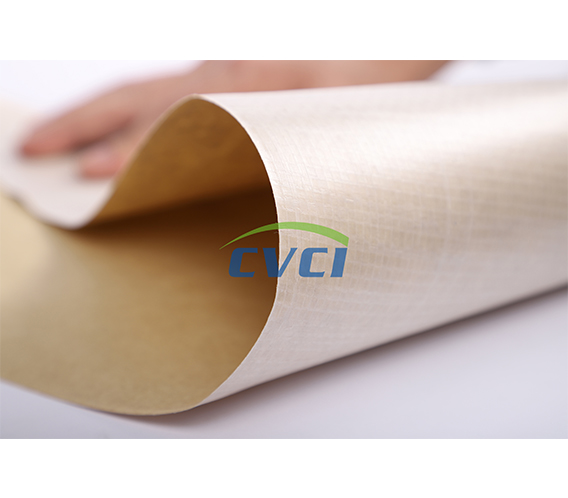

Product introduction:

Barrier type VCI paper is a kind of paper-plastic composite antirust packaging material, which is composed of VCI, antirust base paper, polyethylene film, plastic woven cloth and barrier film. After the product is packaged, the VCI contained in the paper slowly vaporizes and volatilizes at room temperature to form inhibitor steam, which is adsorbed on the metal surface and forms a molecular protective film, thus playing an excellent role in VCI antirust protection. At the same time, it can also play an excellent contact antirust effect when contacting metal. The barrier layer can effectively prevent the external environment water vapor from entering the packaging space, thus reducing the risk of condensation and the risk of moisture corrosion on the metal.

Product features:

The barrier type VCI paper has excellent VCI antirust protection and contact antirust performance.

This product has excellent barrier performance, and its barrier to water vapor is higher than that of ordinary antirust paper. Its moisture permeability is equivalent to that of ordinary antirust paper plus a layer of plastic film.

The barrier type VCI paper has excellent physical strength and is suitable for heavy metal packaging.

The barrier type VCI paper is safe and environmentally friendly, free of phosphate, chromate and heavy metals, and safe to use, meeting the requirements of EU RoHS, PFOS, PFOA and REACH directives.

Scope of application:

The barrier type VCI can be used for antirust packaging of common cold plate, galvanized plate, tinplate, chrome-plated plate, oriented silicon steel, non-oriented silicon steel, etc. in metallurgical industry, and also for inner core packaging of steel coils.

Product usage:

Use antirust packaging materials correctly according to GB/T 14188.

Ensure that the surface of the metal material to be packaged is clean and dry.

The barrier type VCI paper shall be protected from contamination during cutting, placing and using, such as foot, bare hand touch

Dripping sweat, condensation, dust and other pollution.

When packaging, pay attention to the paper face of the antirust paper towards the metal.

During packaging, it is forbidden to touch the contact surface of metal and antirust packaging materials with bare hands, and keep the surface of metal and packaging materials clean.

Ensure that the overlap of anti-rust paper is continuously and completely sealed, and keep the packaging intact during loading, unloading, storage and transportation to avoid damage.

The packaging environment should be clean and dry.

The product should be taken and used at any time. If it cannot be used at one time, it should be sealed and stored again. The exposure time of the product in the air shall not exceed 4 hours.

Storage:

The sealed and packaged barrier type VCI paper shall be stored in a cool, dry and rain-proof warehouse to avoid contact with moisture and direct sunlight on the ground, heat source, acid, alkali and other corrosive substances, and the distance from the ground shall not be less than 0.1m.

The storage environment temperature is lower than 40 ℃ and the relative humidity is lower than 85%.

Under the specified storage conditions, the shelf life of the product is 3 years from the date of delivery.