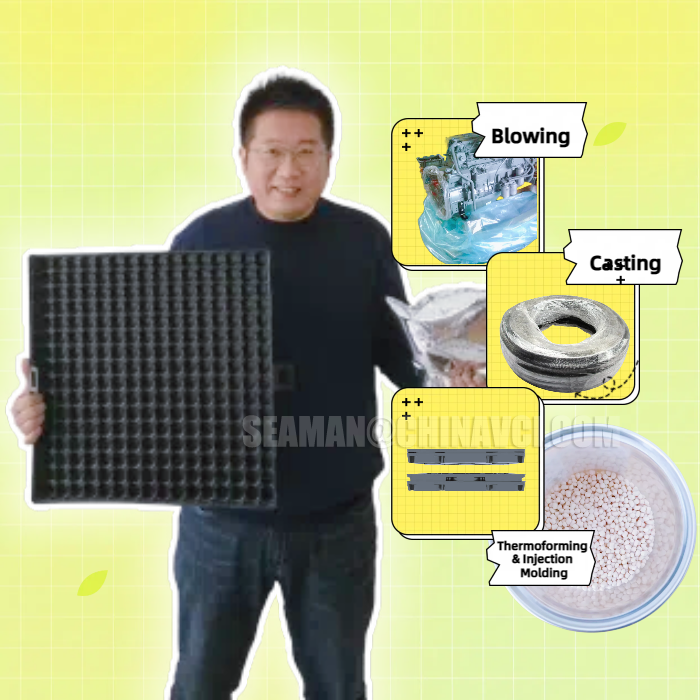

Eco-Friendly VCI Masterbatch (FREE SAMPLE)

0 Nitrite, Less Smoke & Smell

2 % of Dosage, Less Cost & Resource

3 Grade of TL-8135, Higher Corrosion Inhibiting

The Choice of World Packaging Groups

Talk To SEAMAN, Get Best Offer!

Email: SEAMAN@CHINAVCI.COM WhatsApp/WeChat: +86 13704052430

Since 1989, Also Available At CHINA VCI:

VCI Paper, VCI Film, VCI Masterbatch, VCI PP Woven Fabric Raffia, VCI Powder/Desiccant/Emitter/Capsule, Anti-Rust Oil, Multi-Use Anti-Rust Lubricant, Water Based Anti-Rust Liquid...etc.

#VCI #Packaging #Masterbatch #CorrosionProtection #Packing #Resin #Anticorroison #CorrosionInhibitor #Plastico #VapourCorrosionInhibitor

#VCIconcentrate #PVC #PE #SteelWrap #Metals #Blownfilm #Casting #Injection #Eco #CVCI #Seaman

170N VCI Masterbatch

PRODUCT DESCRIPTION

Anti-rust masterbatch is the core material for the production of vapor-phase anti-rust plastic packaging products. Adding a small amount can give products unique Vapors Corrosion Inhibiting capabilities, and has a signi.cant e.ect on preventing rust during the turnover, storage and transportation of metal products. Because anti-rust masterbatch is easy to use and has low technical requirements for equipment and process production, it has been widely used in pro-cessed products such as blow molding, casting, blister molding, and injection molding. This anti-rust masterbatch does not contain nitrite, with less smell, lower addition ratio, and less smoke during the production process, and the blown .lm products are uniform and translucent without a.ecting the physical properties. This product is used for blow molding products and should be added at 2% of the resin weight. It is recommended that the processing tem-perature be controlled at 150℃~165℃. If there are special resin materials that require high-temperature processes, the maximum .lm blowing temperature is 200°C, which can ensure the product's vapors rust prevention performance. However, as the processing temperature increases, a small amount of smoke and odor will be produced, which is normal. This product is suitable for special processing techniques of cast iron, steel, copper and copper alloys, alumi-num and aluminum alloys. Please consult a technical engineer before using this product.

USAGE METHOD

Before using this product, you should wear corresponding labor protection supplies, such as

gloves, masks, etc.

Vapor phase anti-rust .lm production:

Single-sided volatile .lm: 2% of the inner layer isadded with anti-rust masterbatch for .lm blowing.The recommended .lm blowing temperature is150~160℃, the maximum .lm blowing temperatureis 200℃, the screw extrusion ratio is 2:1:1 or 3% ofthe inner layer is added. , the screw extrusion ratiois 1:1:1 for blow molding; double-sided volatile.lm: add anti-rust masterbatch according to 2% for.lm blowing, the recommended .lm blowing tem-perature is 150~160℃, the maximum .lm blowingtemperature is 200℃ for blow molding ;

Use of vapor phase corrosion inhibitors

The anti-rust masterbatch can be packaged innon-woven fabrics, DuPont paper and other pack-aging materials and can be used directly as a vaporphase corrosion inhibitor.

STORAGE REQUIREMENTS

The sealed and packaged vapor phase anti-rust masterbatch should be stored in a cool and dry warehouse. The storage environment requires a temperature below 65°C and a relative humidity below 85%.Open the package when using. During continuoususe, it should also be stored in an airtight, self-sealing container. Without self-sealing packaging containers, exposure to air should not exceed 8 hours.

NOTE

When using this product to process vapor phaseanti-rust .lms, it is recommended to add 2% of thetotal resin weight; the .lm blowing temperature iscontrolled at 150℃~165℃, which can ensure lowsmoke and odor in the workshop during the .lmblowing process; this product has the highest The.lm blowing temperature is 200℃; when using thisproduct, use it according to the .rst-in, .rst-outprinciple. Unused unopened products must be re-sealed to ensure the anti-rust performance of theproduct.